New Elephant Wall at NTU

Currently, only 15% of households in Southeast Asia have an air conditioner 1, but this number is expected to rise, leading to an increase in demand for energy consumption, electricity, and CO2 emissions, which could further worsen global pollution and climate change. There is therefore an urgent need to find alternative solutions to cool buildings and regulate their temperatures.

Nature’s Blueprint: Elephant Skin?

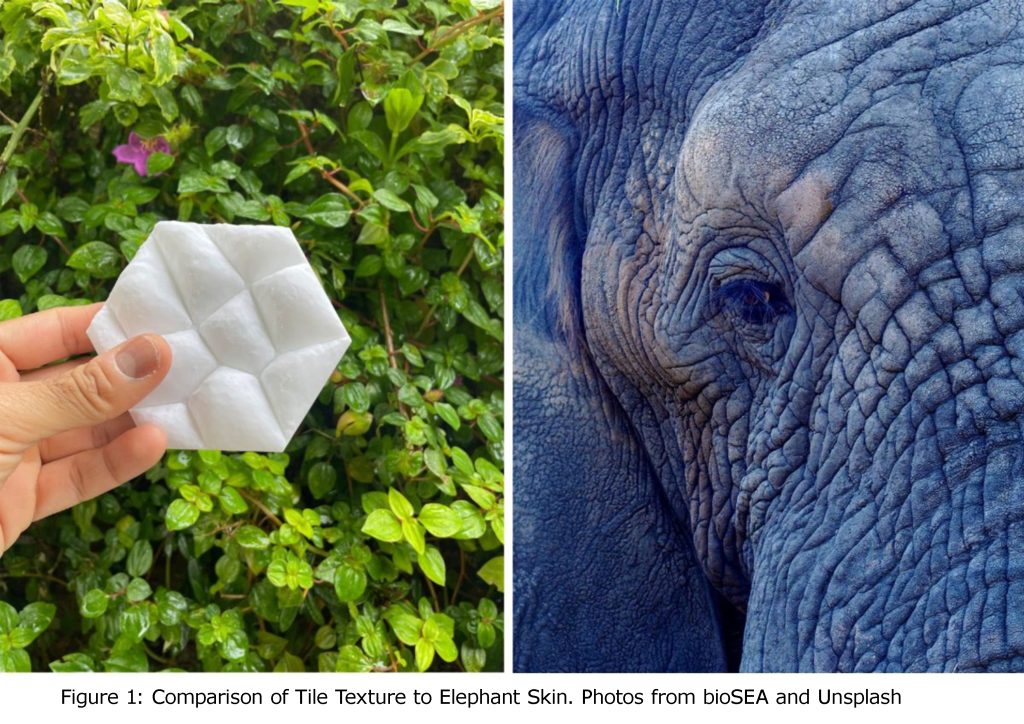

From the blazing savannahs of Africa to the forests of Asia, elephants thrive in heat that would overwhelm most creatures. They don’t sweat or pant. Instead, they rely on something far more subtle — their skin. Thick, cracked, and deeply textured, elephant skin isn’t just armor; it’s a powerful cooling system.

Inspired by this marvel of natural engineering, our team developed elephant skin tiles — façade materials designed to keep buildings cooler in tropical and subtropical climates. These tiles mimic the fractal-like bumps and crevices of elephant skin, using self-shading, evaporative cooling, and water-retaining microcracks to manage heat passively.

Designing Elephant skin tiles

To design our elephant skin tiles, we used evolutionary algorithms that mimic natural selection to find optimal cooling patterns.

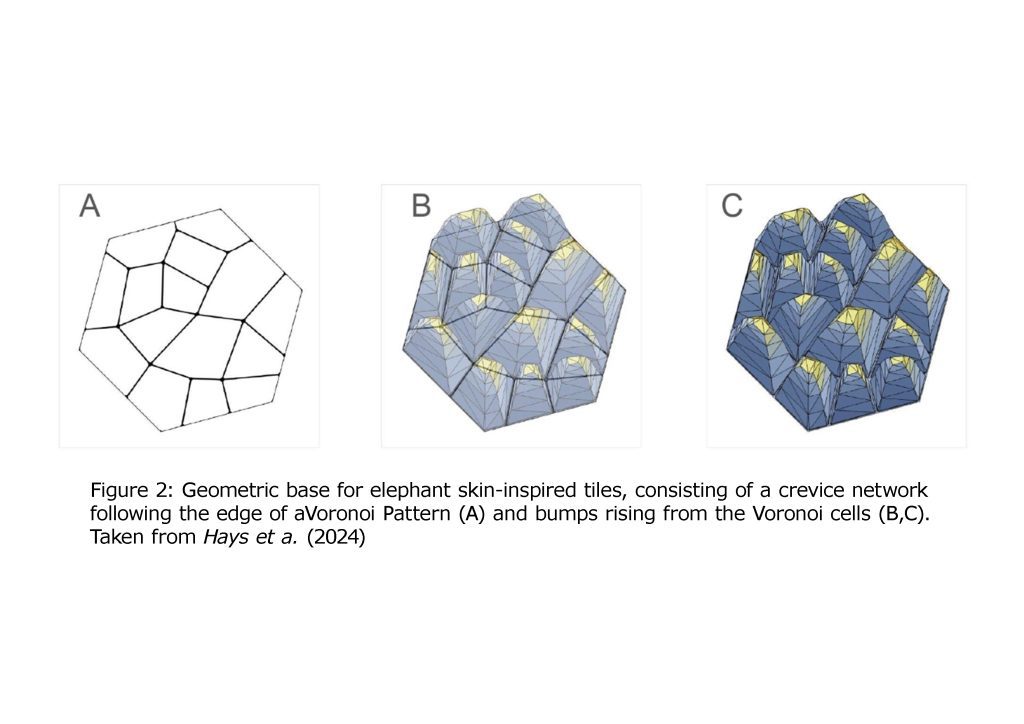

The process2 began by creating a digital base geometry using Voronoi patterns, where each cell represented the foundation for a bump, and the cell edges became the crevices between bumps. We developed a computer script that could generate hexagonal tiles with a 10 cm diameter, incorporating pseudo-random arrangements of these Voronoi cells. Each tile design was controlled by digital “genes” that determined the number of bumps, their heights, and their positioning across the surface.

The evolutionary algorithm then generated hundreds of tile variations and tested each one against virtual sunlight simulations in Singapore and Phoenix (Arizona, USA). Singapore was chosen due to its wet and humid climate while Phoenix was chosen for its hot and dry climate. Performance was measured by comparing how much solar radiation hit the bumpy tiles versus flat control surfaces. The best-performing tiles from each generation were selected to “reproduce,” mixing their successful traits to create improved designs for the next generation. Occasionally, random mutations were introduced to explore new possibilities.

This cycle continued through thousands of generations until the algorithm evolved tile patterns that demonstrated measurable cooling advantages.

Interested to read more? Find our research paper on elephant skin tile design here.

Mycelium as a Building Block

Collaborating with NTU scientists, biodegradable tiles were developed using mushroom fibers. The process begins by mixing bamboo fibers, oats, and water, then adding mushroom spores before packing the mixture into molds. These molds are kept in a warm, humid environment for two weeks. After removal from the molds, the tiles undergo oven drying, with the entire process taking approximately 31 days. The resulting material is both lightweight and durable, suitable for outdoor applications like insulation. For additional details on the process, do read the blog by Le Ferrand research group on mycelium fabrication3.

Revolutionising Performance

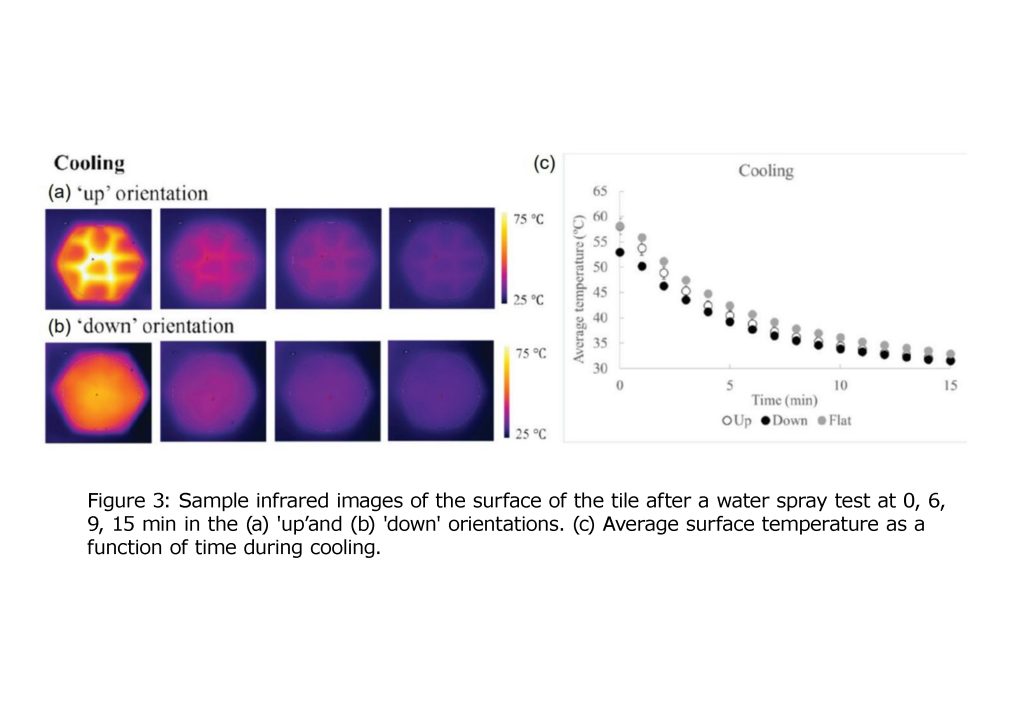

Laboratory testing revealed promising results. Compared to flat mycelium tiles, the elephant-skin-inspired tiles displayed a 25% improvement in cooling performance and a 10% lower surface temperature of buildings when placed on their flat side, providing an energy-efficient method to mitigate urban heat. Rough grooves on the surface allow for concentration of heat in these areas (Figure 3 reproduced from Soh et al. (2025)4).

Under simulated rain conditions, the cooling efficiency of the textured tiles increased by an impressive 42%, due to adhesion of water droplets on the tiles’ surface despite mycelium’s hydrophobic properties. These tiles have immense potential for working in tropical regions where humidity and heavy rainfall are part of routine weather, like our concrete jungle — Singapore.

Handmade clay

Two other materials were tested, clay and concrete. The clay tiles were handmade in Singapore using local clay and food waste by Ferticlay. The tiles were molded in silicone molds before being removed and air-dried. We conducted a three day temperature test outdoors for all three tile materials at Sprout Hub, Singapore.

Among the three materials, clay is the only tile group that has shown increases in temperature compared to the background. Clay tiles also had unpredictable cooling patterns, having the most temperature fluctuations during the monitoring period. Finally, the clay tiles are not baked in view of the huge carbon footprint it would create, this limits their feasibility for outdoor use. A wax coating was applied to waterproof the tiles but it wore off within a month, rendering it ineffective for long-term use in the elements.

Recycled concrete

The concrete tiles were manufactured at a solar powered facility in India, using about 25% of recycled concrete and local pigments for vibrant colours. After the three day temperature test outdoors (at a facility separate from the NTU wall), we found that concrete tiles demonstrate consistent cooling performance, without the erratic temperature fluctuations observed in clay tiles. While as a whole mycelium achieved slightly higher heat reductions than concrete, mycelium tiles are susceptible to degradation from UV rays and rainy conditions. Thus, the consistent behavior of recycled concrete, combined with its inherent weather resistance and durability, positions it as the optimal choice for sustainable building applications where long-term outdoor performance is essential.

Tile Installation

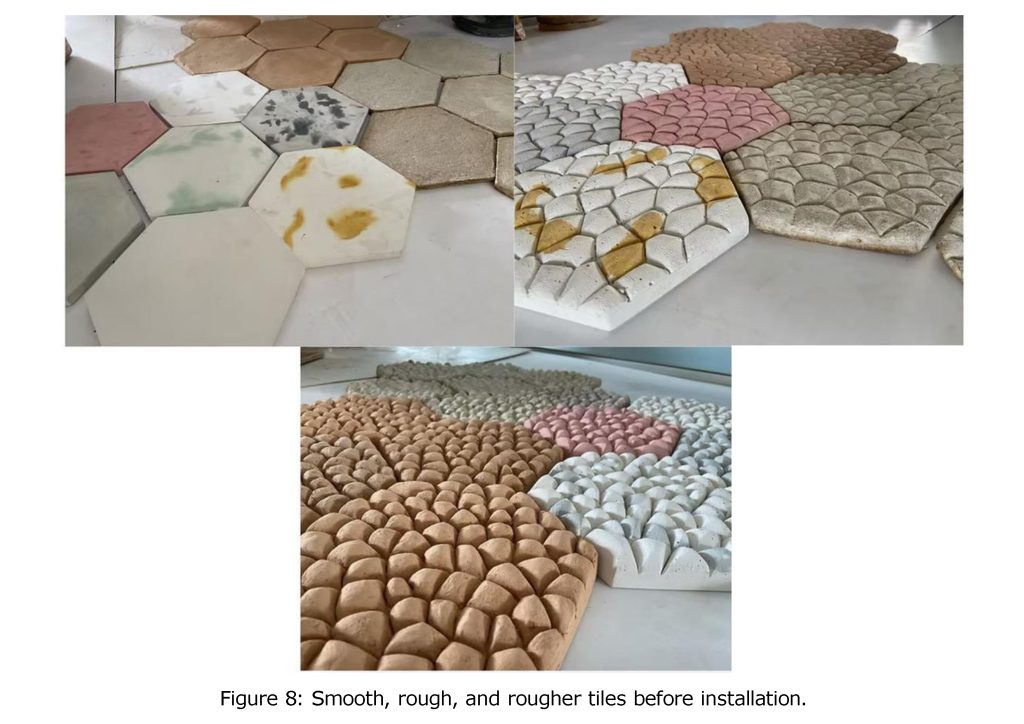

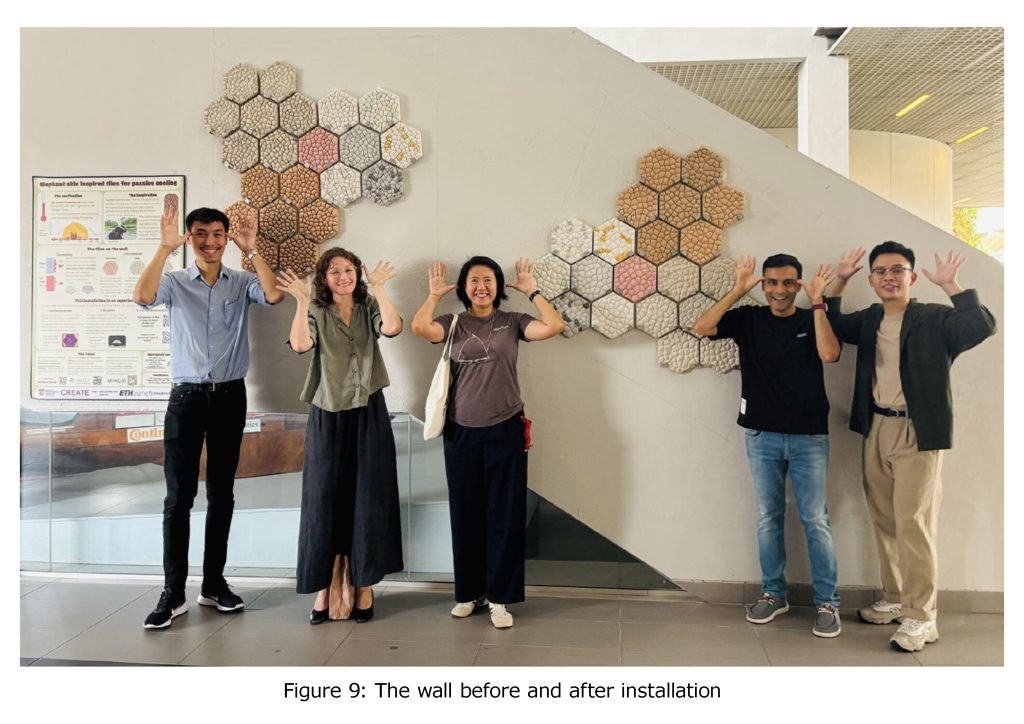

The installation at NTU is an experiment to better assess these tiles’ performance in Singapore’s tropical context. Three different textures: smooth (no texture), rough (small texture), rougher (more texture with taller bumps), and three different materials: recycled concrete, known for its durability but high thermal mass, clay, which is traditional and breathable with moderate insulation capacity, and mycelium. Each combination of material and texture is monitored using temperature sensors and visible degradation as a test of durability. This installation will help answer the question of whether biomimicry can be used to outperform traditional building tiles in passive cooling performance.

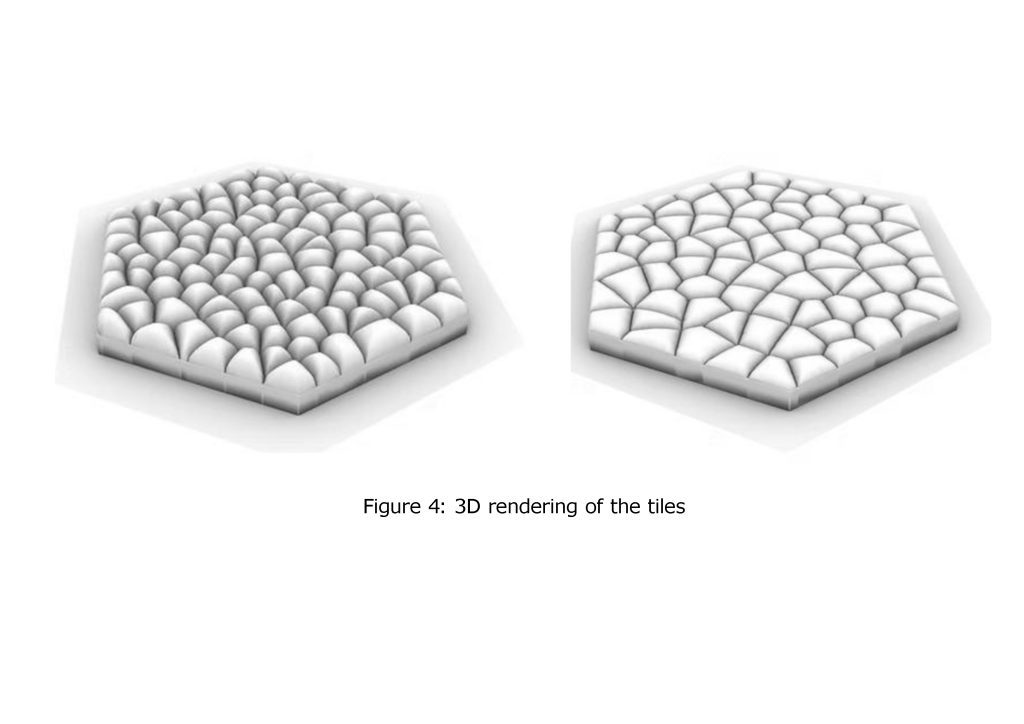

To make the tiles for the installation, we collaborated with Mykilio, Ferticlay, and NTU scientists. Our team generated CAD models of the tiles (Figure 4) that were then 3D printed using fused deposition modeling (Figure 5). Silicone molds were produced (Figure 6). The final tiles were molded in the molds (Figure 8) and installed on the wall using brackets and mortar (Figure 7).

You can come and see the installation at NTU North Spine Level 2, at the entrance of the School of Mechanical and Aerospace Engineering. Once there, please access the QR code on the poster to provide your feedback and input.

Associated Links